Beverage Filling Machine Wireless Bridge Application

Background

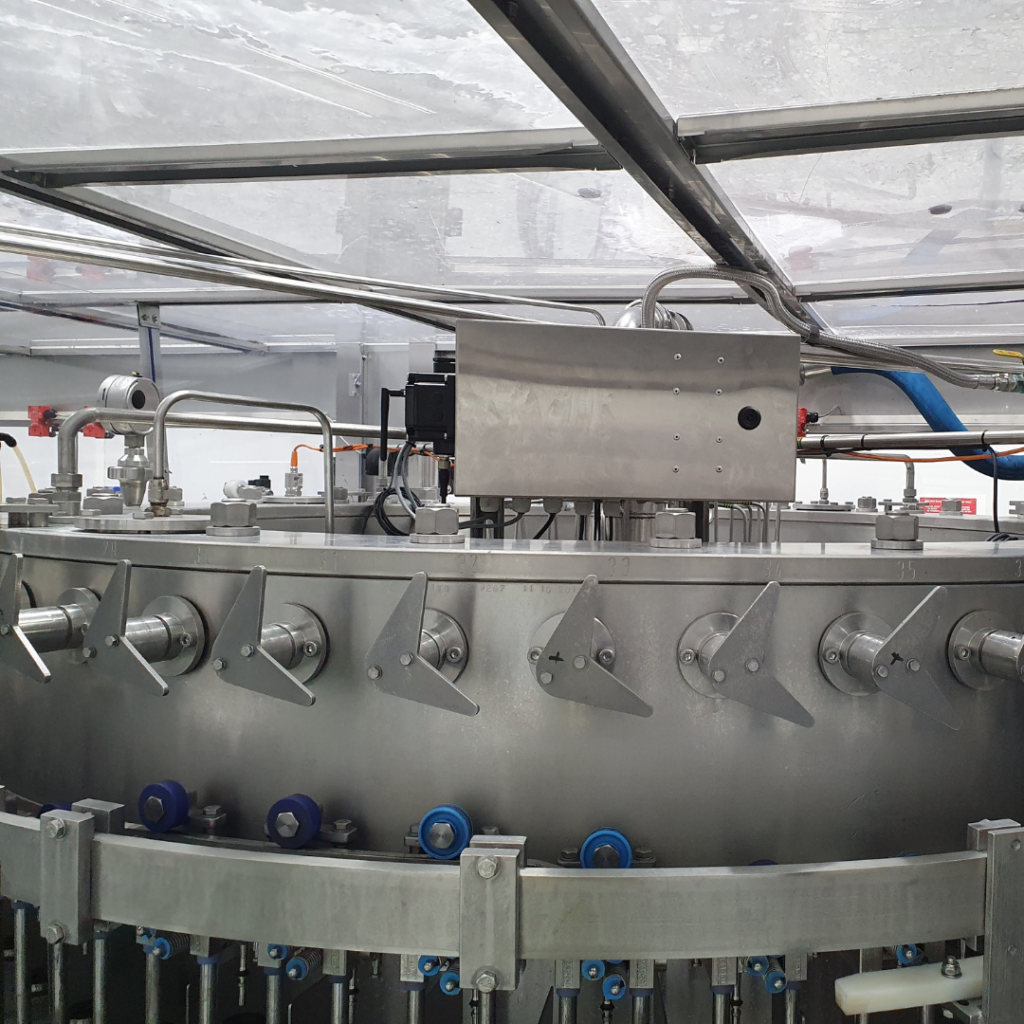

Our team was approached with a challenging task: to devise a slip ring replacement solution for a rotary bottle filling machine. The machine’s critical functionalities depend on precise measurements obtained from a pressure transmitter and guided wave radar, crucial for maintaining bottle fill levels and product carbonation. However, the existing slip ring system, despite being an industry standard for power transfer, posed reliability issues, particularly with low current signal transfer. Reported issues included short circuits, erratic rotation, inadequate ingress protection and burnout, significantly affecting the filling process and product quality.

Challenge

The project presented three primary challenges. The machine’s rotational nature demanded a solution capable of accommodating continuous movement without compromising signal integrity. Eliminating the slip ring meant the solution couldn’t rely on power sources within the rotating part of the machine. Also the machine’s Cleaning In Position (CIP) process required a solution with a high ingress protection rating to withstand rigorous cleaning procedures.

Solution

After careful analysis, we determined that only a self-contained wireless battery-powered signal transmission system could effectively address these challenges. We devised an innovative solution consisting of the following components.

We designed a robust enclosure housing the wireless node, battery pack and signal marshalling terminals. Special attention was paid to ensure the battery’s accessibility for easy replacement and recharging. Utilizing standard Makita machine tool batteries ensured simplicity, safety and availability for replacement if necessary.

The signals from the pressure and level instruments were hardwired into the wireless node, which transmitted them wirelessly via Modbus protocol through a bulkhead antenna to a gateway radio situated at the control panel. The gateway then converted these signals back to hardwired 4-20mA analogues, which were connected to the PLC analogue input module.

Result

Following the successful implementation of the wireless system, we proceeded with installing temperature sensors and integrating all signals into the energy calculators. The commissioning of metering systems for all 19 circuits was completed, enabling accurate energy consumption data collection.

Conclusion

By leveraging innovative engineering and wireless technology, we successfully addressed the challenges posed by the rotary bottle filling machine’s slip ring replacement. The implemented solution not only ensured reliable signal transmission but also improved operational efficiency and product quality. This case highlights our commitment to delivering tailored, efficient solutions to complex industrial challenges.