Liebherr P78 Moisture Monitoring on Digestate Dryers

Background

Process Instrument Solutions supplied and commissioned a Liebherr P78 moisture monitoring system at a digestate drying facility within the British Sugar plant in Bury St Edmunds. Accurate moisture measurement is critical in this process, as inadequately dried granules can become sticky, leading to “brown outs” — significant blockages in the production line. These blockages often require extensive manual intervention and clearing, potentially halting production for 2–3 days.

Challenge

Positioning a moisture sensor within an enclosed digestate dryer presents several challenges. The primary concern is identifying a location where the sensor can maintain consistent contact with the material, despite the digestate moving along the dryer bed at approximately 1 meter per minute and often at varying levels. Additionally, the high temperatures and abrasive nature of the digestate necessitate the selection of robust instrumentation capable of withstanding such harsh conditions.

Solution

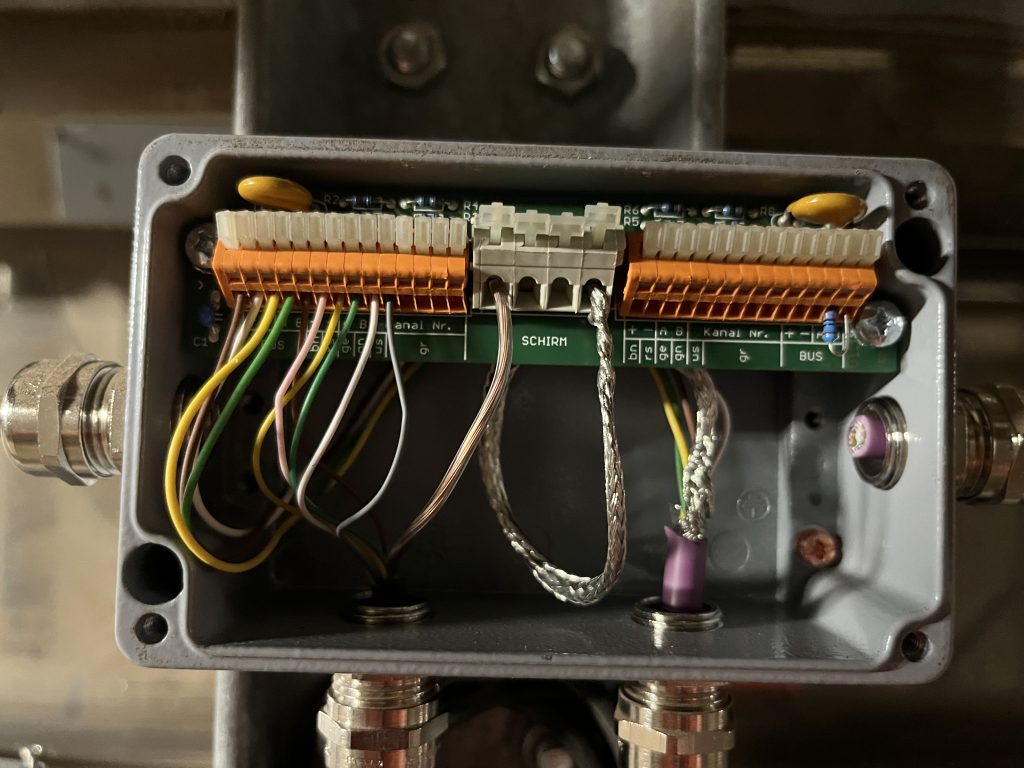

The P78 sensor was mounted on a sliding shoe, allowing it to maintain constant contact with the digestate. The elbow design enables the sensor to rise and fall with the product level, accommodating the variable flow of material. To withstand the high temperatures inherent in the drying process, the high-temperature sensor option was selected, ensuring reliable performance under thermal stress.

This configuration ensures accurate, continuous moisture measurement, which is critical for preventing brown outs. By maintaining optimal moisture levels, the system enhances product quality and reduces the risk of production downtime. It also ensures minimum energy consumption as the product doesn’t need to be over dried.

Result

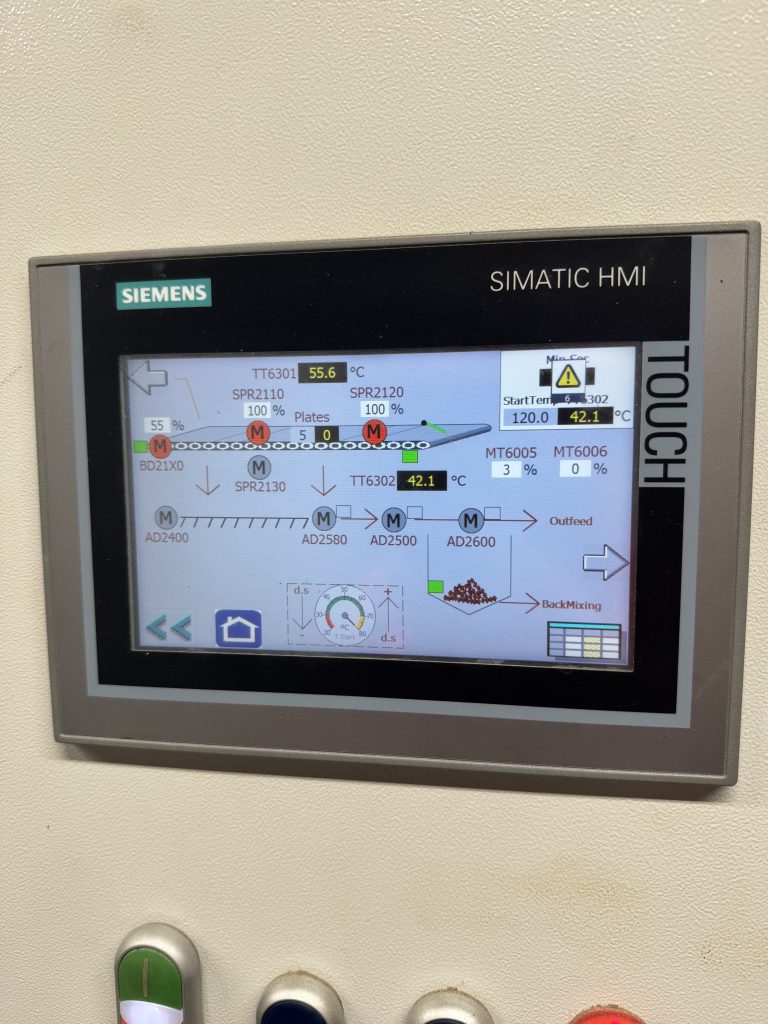

The integration of the Liebherr P78 moisture sensor has significantly enhanced operational efficiency at the digestate drying facility. By providing operators with real-time moisture measurements, the sensor enables proactive process control, allowing for timely interventions to prevent brown outs.

This real-time data empowers operators to make informed decisions in managing the drying process, optimising dryer settings to maintain consistent product quality. Moreover, it facilitates energy savings by preventing over-drying, which not only conserves energy but also reduces wear on equipment. Such optimisation leads to increased production efficiency and a significant reduction in energy consumption.