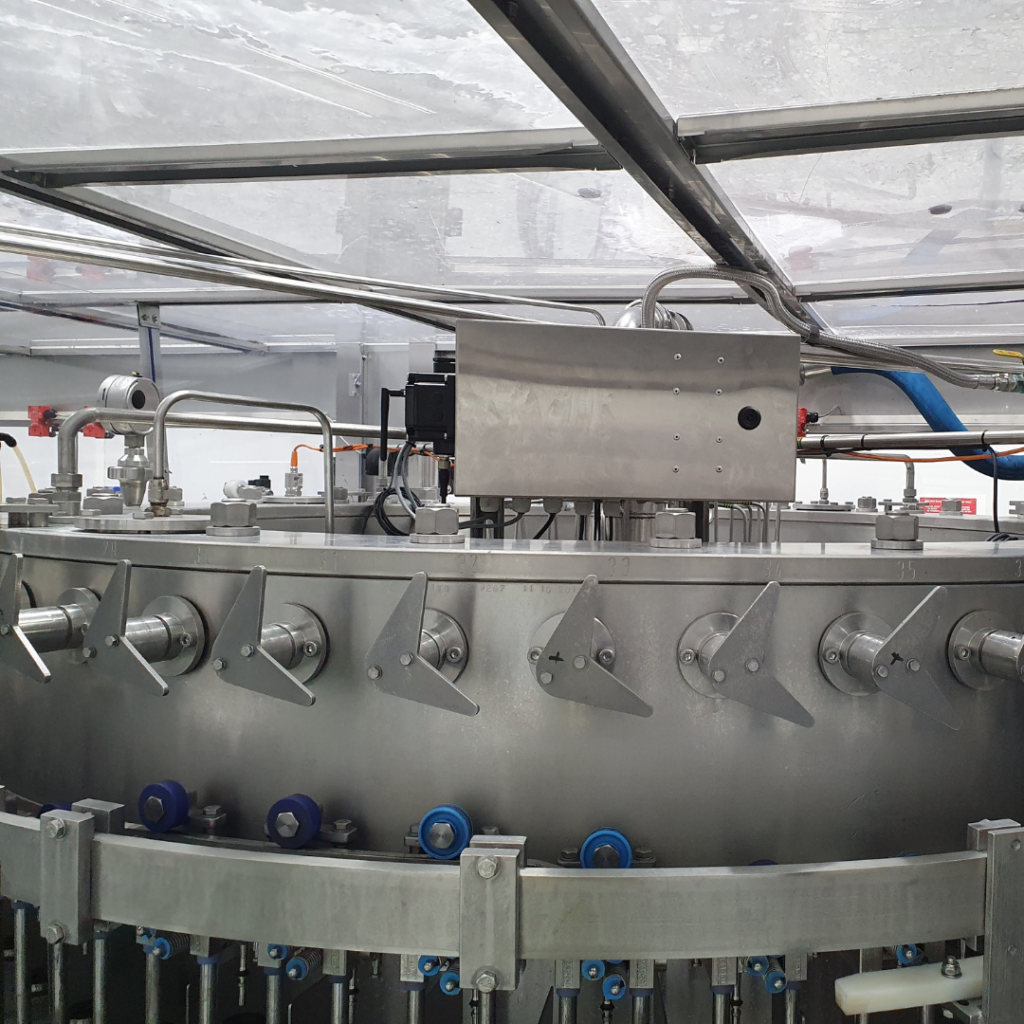

At Process Instrument Services, we understand that every industry has unique requirements, which is why all our services are fully customisable. Whether you're in manufacturing, pharmaceuticals, energy or any other sector, we tailor our solutions to meet your specific needs. From design and installation to maintenance and calibration, our flexible approach ensures that our instrumentation systems integrate seamlessly with your operations. This adaptability allows us to provide reliable, efficient and compliant solutions for any industry, helping you maintain optimal performance and meet regulatory standards.

Oil & Gas

Exploration, Refining, and Processing: Process engineers design systems to optimise extraction, refining, and transportation of oil and gas. This involves designing processes like distillation, cracking, and heat recovery to ensure operational efficiency and regulatory compliance.

Offshore and Onshore Facilities: Engineering solutions are essential for managing high pressures and temperatures in extreme environments.

Chemical & Petrochemical

Chemical Manufacturing: Designing reactors, separators, and heat exchangers for chemical processes is key to ensuring the efficient production of bulk chemicals, fine chemicals, and industrial gases.

Petrochemical Plants: Engineers design the transformation of crude oil derivatives into petrochemical products like plastics, synthetic fibres, and resins, ensuring process control, safety, and environmental sustainability.

Food & Beverage

Food Processing: Process engineering is vital in designing systems for mass production of food, including pasteurisation, sterilisation, mixing, and packaging. This ensures food safety, quality, and regulatory compliance.

Automation: Engineers design automated processing systems to optimize efficiency, reduce waste, and ensure consistency in food and beverage production.

Energy & Power Generation

Thermal Power Plants: Process engineers design systems to convert fuel (coal, gas, biomass) into electricity through efficient combustion, steam generation, and turbine operation.

Renewable Energy: Engineers design processes for converting wind, solar, biomass, and geothermal energy into usable power, optimising energy capture and grid integration.

Water & Wastewater Treatment

Water Purification: Engineers design systems for desalination, filtration, and chemical treatment to provide safe drinking water or water for industrial use.

Wastewater Management: Process design is crucial for treating industrial and municipal wastewater, removing contaminants, and ensuring compliance with environmental regulations.

Metals & Mining

Mineral Processing: Process engineers design systems for crushing, grinding, and separating valuable minerals from ores, ensuring energy-efficient and cost-effective recovery.

Smelting and Refining: Engineers design the processes that convert raw materials into pure metals and alloys, focusing on optimizing furnaces, electrolytic cells, and waste management.

Pulp & Paper

Paper Manufacturing: Engineers design processes to convert wood pulp into paper, focusing on energy efficiency, waste reduction, and the use of environmentally friendly chemicals.

Recycling: They also design systems for recycling paper, removing inks and contaminants to produce high-quality recycled products.

Construction Materials

Cement and Concrete Production: Process engineering is critical in optimizing the production of cement, concrete, and other building materials, focusing on energy efficiency and emissions reduction.

Glass and Ceramics: Engineers design processes for producing and shaping glass and ceramic materials, optimizing kiln operations, and material handling.

Environmental & Sustainability Engineering

Waste Management: Engineers design processes for recycling and waste-to-energy plants, transforming waste materials into usable resources or energy.

Sustainable Process Design: Process engineers focus on reducing emissions, energy consumption, and waste generation in various industrial processes, ensuring environmental compliance.